Deriving from the strong adherence of the founders of Mitsuba to “create our own production lines”, we continue to develop our own production equipment and tools, including digitally-controlled automated processing machines, assembly machines, testers, and the majority of jigs and molds.

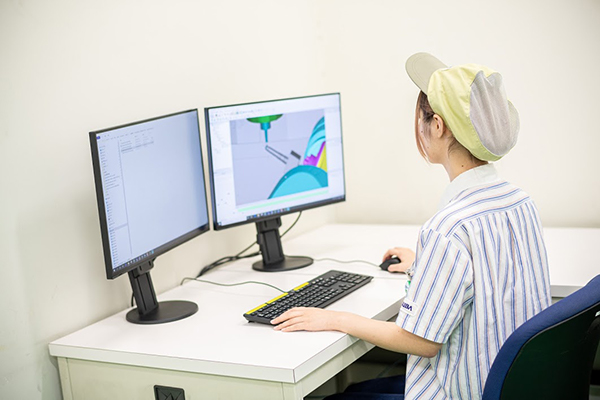

In developing equipment, jigs and molds, we continue to streamline our development process by using the latest technologies including 3D printers and X-ray CT, in addition to CAD/CAM/CAE.

We also use cutting-edge technologies such as robotics, AI, and IoT in our production systems to help build flexible and rational production lines. We now aim to build a “flexible and no loss production system” in combination with developing parts machining technologies to accelerate the machining process and reduce costs, such as introducing automated processing machines that run 24 hours a day.

Mitsuba is also optimizing production globally by developing region-specific equipment and introducing production systems enhanced by the strength of each region.

As we continue to build systems that allow us to self-manufacture equipment and molds in Indonesia, Vietnam, and China, production technologies are being bolstered in Mexico and India. The role that production technologies play in order for our production network, which spans from the Americas to Europe, Asia, and China, to fully function continues to grow every year.

Through intensified efforts in production engineering, we will continue striving to develop new products with improved quality.

Aiming for the evolution of technology in harmony with society and the environment, we are promoting efforts such as reducing CO2 emissions by decreasing the power consumed by production equipment in an effort to achieve carbon neutrality, improving the yield of raw materials and indirect materials, and using recycled materials.

Simulation

Simulation Research Prototype

Research Prototype 3D CAD Design

3D CAD Design Creation of Equipment

Creation of Equipment 3D Printer

3D Printer 3D Measuring Machine

3D Measuring Machine